Environmentally friendly hot-dip zinc chromium-free passivation process

Nov 09,2020

As an economical and simple surface treatment process, hot dip galvanizing is widely used in all walks of life. As a post-treatment process of hot-dip zinc, passivation treatment can improve the corrosion resistance of hot-dip zinc and protect it from premature coating corrosion during transportation and use. Its importance is self-evident.

The passivating agents used in modern hot-dip zinc process can be divided into two main categories: one is chromate passivation, which is easy to cause environmental pollution due to hexavalent chromium, and in recent years, countries around the world have restricted the use of hexavalent chromium. The second is chromium-free passivator, which is a process that replaces chromate passivation in response to environmental requirements and has made great progress in recent years.

The research on chromium-free passivating agents to replace chromate has a variety of directions, such as molybdate, cobalt salts, rare earth metals and so on. Taking molybdate as an example, metal molybdenum is less toxic. The corrosion resistance of the coating after molybdate passivation is comparable to that of chromate passivation. The molybdate passivation film varies depending on the passivation time and is usually blue or green. Some molybdate passivator in the use of high temperature or passivation time is too long will lead to micro cracks on the surface of the passivation film, making the product neutral salt spray ability is not good.

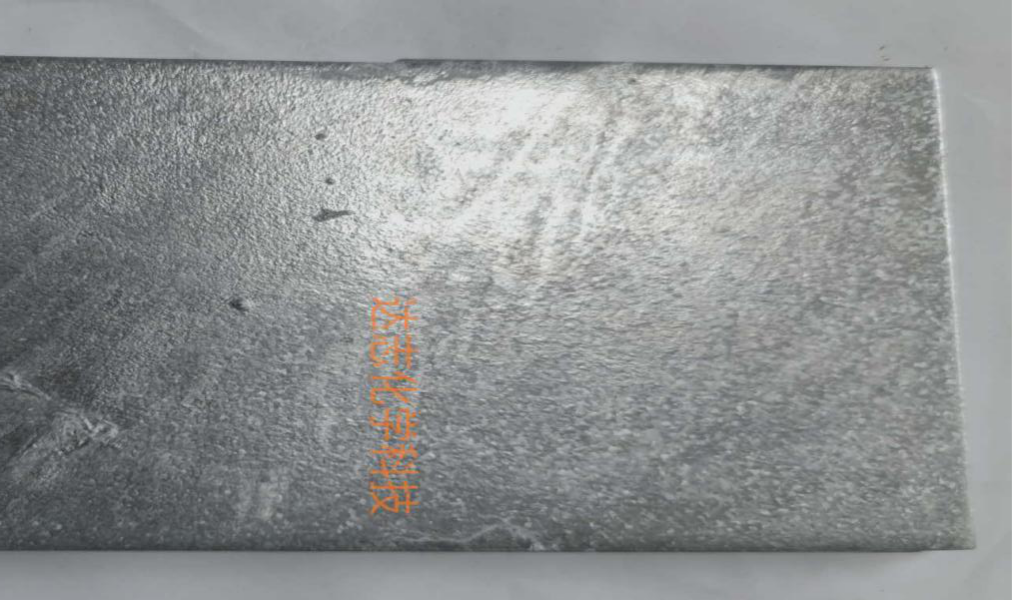

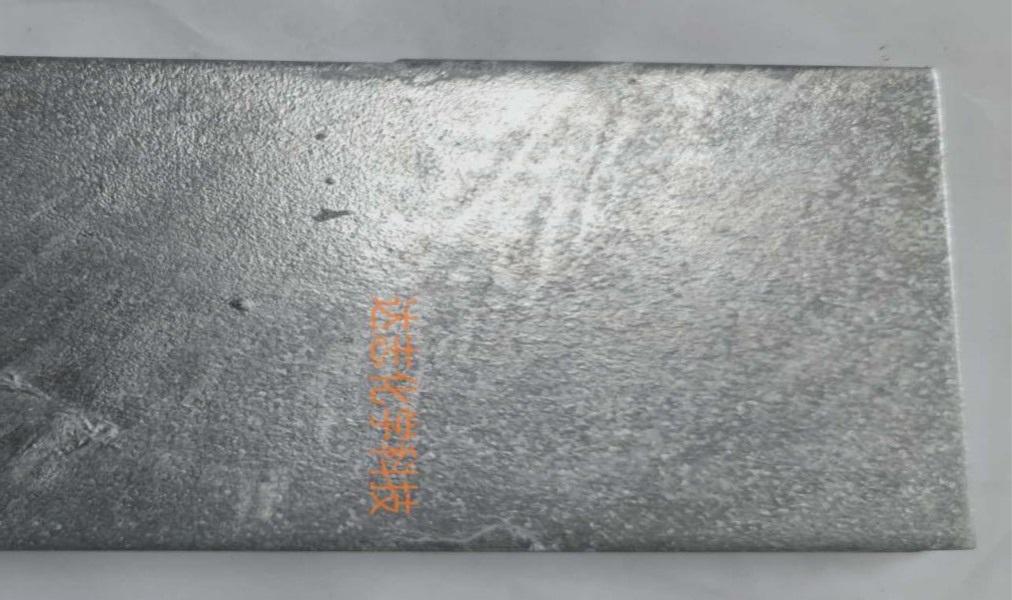

Dazhi Chemical has a mature HKS-200 of chromium-free passivation products, which has excellent corrosion resistance, excellent fingerprint resistance and paint film adhesion. The chromium-free passivator is not only suitable for hot-dip zinc, but also suitable for electro-galvanizing, hot-dip zinc-aluminum alloy, electro-zinc-tin alloy and other processes. Use at room temperature, dry at 60-80 ℃ directly after dipping or spraying, without washing.

Contact Us

E-mail:

sales@dazhichem.com

Phone/WeChat:

+86-18520125168

Address:

No.1 Tianyuan East Road, Yonghe Economic Zone, Huangpu District, Guangzhou City