Product Categories

Focusing on the research and manufacturing of environmentally friendly additives for surface treatment

Established In 2002

A high-tech enterprise dedicated to the development, production and sales of electroplating additives

Was founded in

Technical R&D Team

Global cooperative countries

Manufacturing Base

About Dazhi

Guangdong Dazhi Chemical Technology Co., Ltd. is a wholly-owned subsidiary of Guangdong Dazhi Environmental Protection Technology Co., Ltd. (stock code: 300530). It is a high-tech enterprise dedicated to the development, production, and sales of electroplating additives. We have independent core technologies and collaborate with authoritative research institutions and researchers both domestically and internationally. We absorb advanced research and development concepts from around the world and combine them with the actual needs of domestic and foreign enterprises to develop products that meet the different needs of our customers.

Our advantages

According to your needs, one-stop procurement

Professional Focus

The company has been committed to the research, development, production and sales of environmentally friendly surface treatment additives for more than 30 years and has independent innovative core technologies.

Quality Assurance

Implement IS09001:2015 and IATF 16949:2016 quality management systems to ensure the stability of product quality

Cost Advantage

Direct sales from powerful manufacturers to achieve quality assurance and optimal cost

One-Stop Shopping

Can provide customers with a full range of surface treatment products and solutions

Customization

According to customer needs and requirements, develop products that meet the different needs of customers

Environmental Friendly

We have always adhered to the research and development concept of green cleaning, environmental protection and energy saving, and continue to pay attention to new specifications and standards to ensure that our products meet industry standards while helping customers achieve sustainable development!

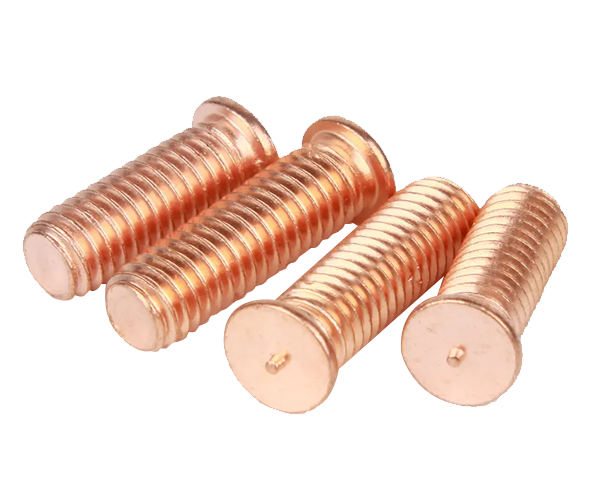

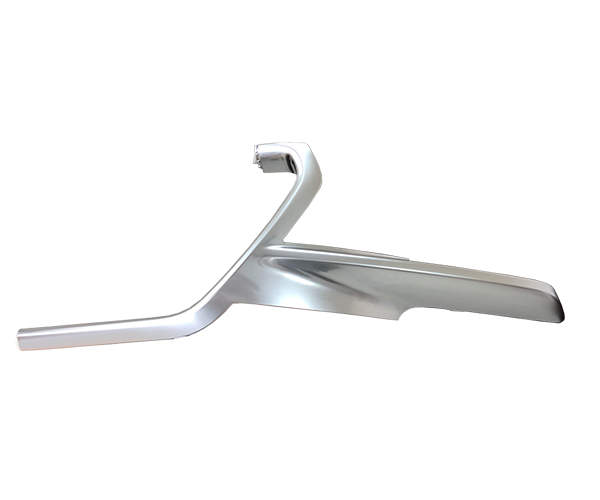

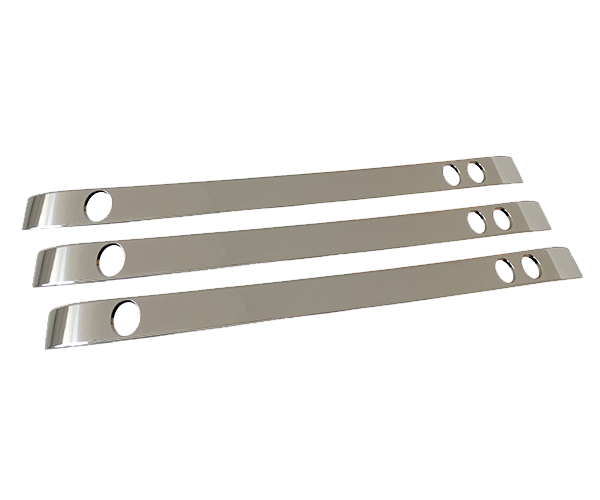

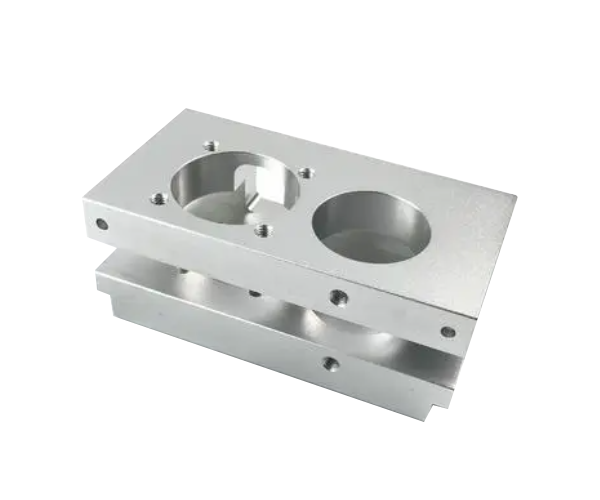

Application Area

For many years, we have been focusing on zinc nickel electroplating additives, sealers, passivators, and chromium free passivators in the field of electroplating additives

Technical Information

Follow Dazhi Information to learn more real-time industry news

Dazhi Chemical 315 Alkaline Zinc-Nickel Alloy Process

Since its inception, zinc-nickel alloy has been widely concerned by the electroplating industry because of its unparalleled advantages in corrosion resistance. With the continuous development of zinc-nickel alloy, it has been used in hardware, automobile, electronics, aerospace and other fields.

Brief Introduction of Commonly Used Galvanizing Alloy Process

Zinc-based alloys have excellent corrosion resistance. Binary or ternary alloys of zinc and other metals can be obtained by electroplating. Most zinc alloys have better corrosion resistance than pure zinc and can effectively reduce the thickness of the coating.

Effect of Metal Impurities on Potassium Chloride Zinc Plating

Metal impurities often pose a great danger to the electroplating working solution. Acid potassium chloride zinc plating is most often affected by iron impurities, followed by copper, lead and other metal impurities are also harmful.

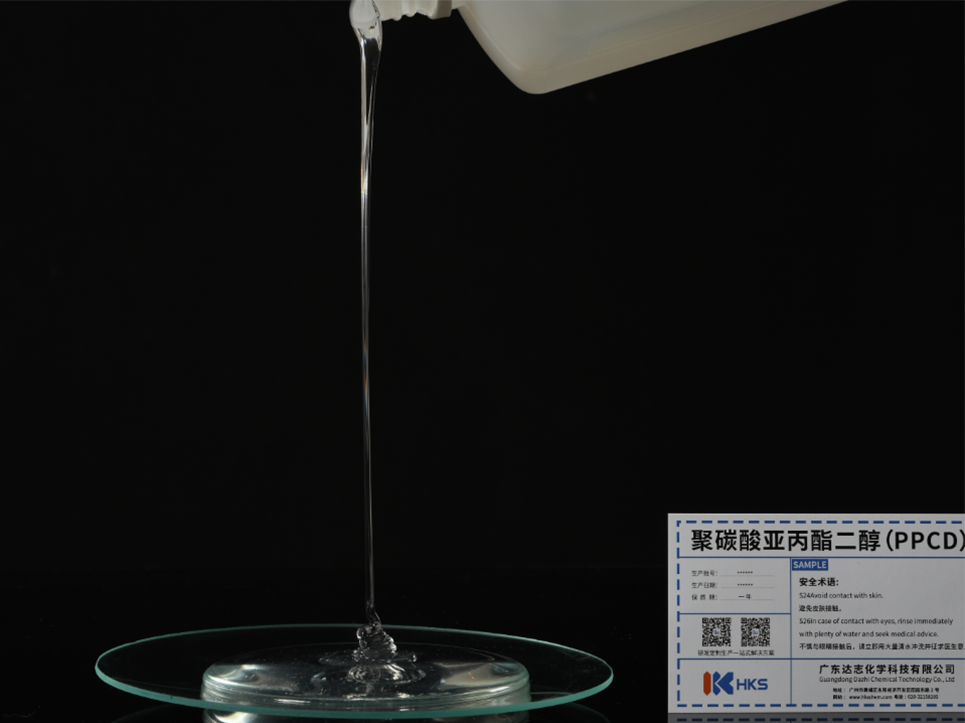

What is the effect of polypropylene carbonate diol

Poly (propylene carbonate) diol (PPC) is an aliphatic diol with high mechanical properties and high hydrolysis resistance.

Please Give Us A Message

According to your needs, one-stop procurement