Products

Contact Us

E-mail:

sales@dazhichem.com

Phone/WeChat:

+86-18520125168

Address:

No.1 Tianyuan East Road, Yonghe Economic Zone, Huangpu District, Guangzhou City

Acid copper additive

ULTRA Acid Bright Copper Plating Process

DZ-007 High Leveling Acid Copper Brightener

DZ-661 Barrel plating acid copper brightener

DZ-662 Acid copper brightener for plastics

DZ-663 Acid copper plating brightener

DZ-200 Printing barrel plating acid copper additive

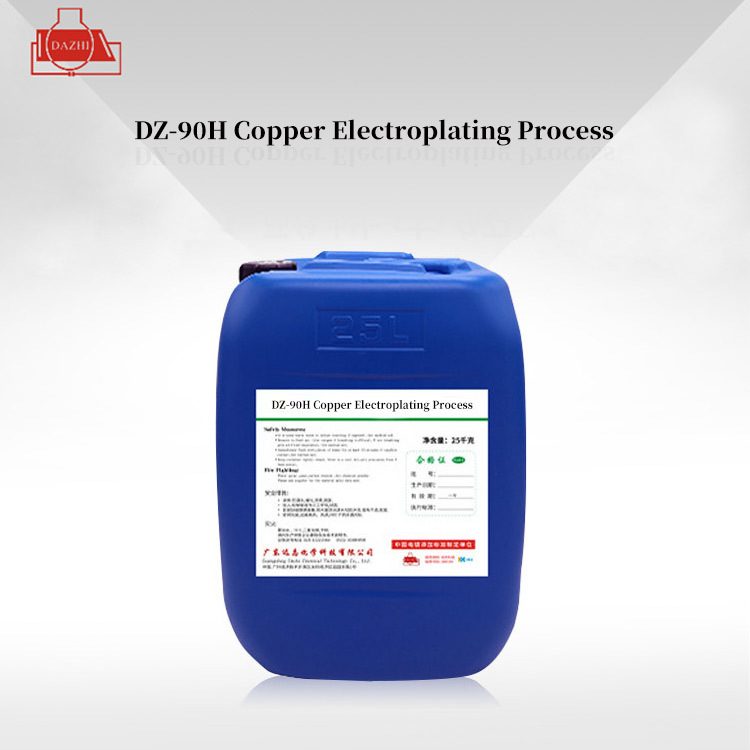

DZ-90H Copper Electroplating Process

DCu-3200 copper sulphate additive